Trifecta GK20 CNC Cut out Shower Door Machine

Brand GTM

Product origin CHINA

Delivery time 60 Days

Supply capacity 20 sets/month

Certified By CE, SGS

General Description

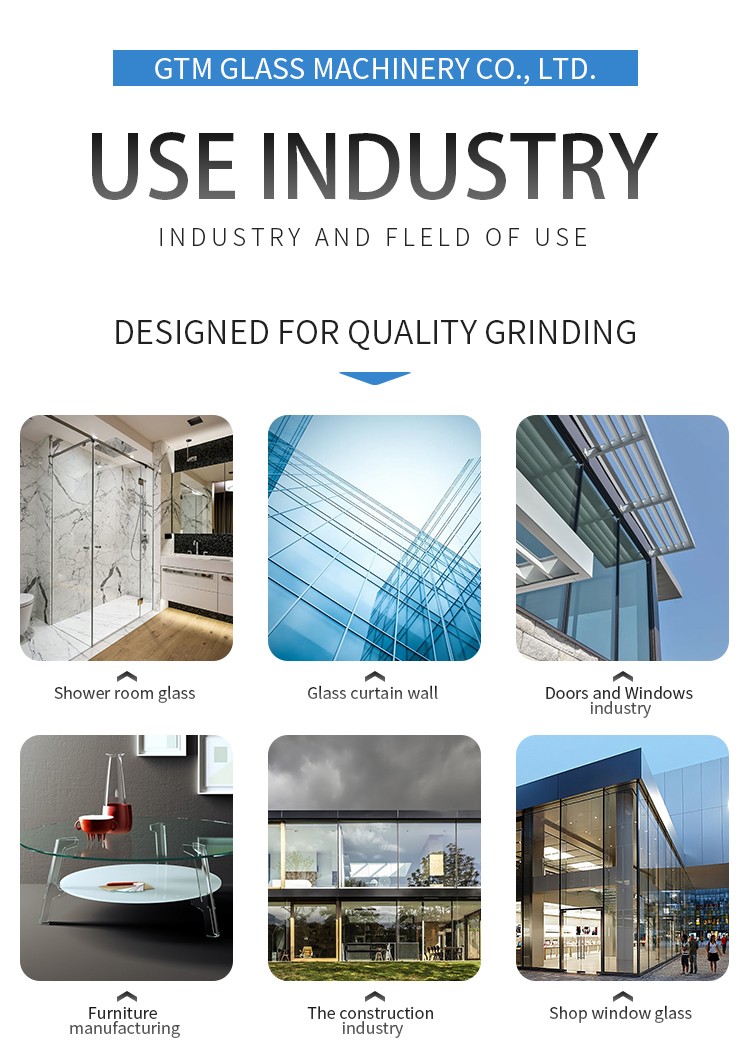

1.GK20 CNC Glass Cut out machine is designed for drilling hole, doing notches, cut-outs on glass sheets with the thickness of 5-19mm. It occupies a small floor space and can do the work automatically and easily. It dose not require the operators have any experience, the machine knows all majors setting and does all operations automatically.

2. With high production efficiency, adopts full servo control, and Graphical User Interface (GUI),

3. There are patterns set inside the machine, just choose the right one and input parameters data you want, then press one button, the machine will get the job done.

4. the machine is adopted with a bottom drill, a top drill, a diamond blade, and a milling cutter.

5. the machine brings a better finishing cut-outs than water jet, and finish the job faster than a traditional CNC center.

6. the machine occupied less space than water jet and CNC working center.

7. Stable performance, simple operation, no vibration, low noise, lower costs on toolings, less maintain, and simple adjustment.

TRIFECTA GK20 CNC SHOWER DOOR Machine

GK20 CNC CUT OUT MACHINE(Specialize in Shower door cut outs)

General Information:

1. The GK20 glass cut-out machine is a high-precision CNC equipment specially designed for shower doors and other glass that requires cutting and slotting. This machine adopts the structure of lower drilling, upper drilling, diamond saw blades, and milling cutters, and is specifically used for combined and efficient processing on glass sheet with a thickness of 5-19mm.

2. This machine has high production efficiency and adopts full servo control and a graphical operation interface (GUI).

3. The machine is internally equipped with a graphic mode. Just select the correct graphic mode and enter the required parameter data, and then press the button, the machine will automatically perform all operations without the operator having any experience.

4. This machine has a better processing effect than the water jet cutter, lower power consumption, and can complete the work faster than the traditional CNC machining center, and saves more tool costs.

5. The machine has a small floor area and takes up less space than the water jet cutting and CNC machining center.

6. The performance is stable, the operation is simple, there is no vibration, low noise, less maintenance, and simple adjustment.

Technical Parameter:

1. Max.Processing size of Cut-out:250mm(L)*250mm(W)

2. Processing Thickness:5‐19mm

3. Height of working table:900±30mm

4. Power:≈8KW

5. Weight:≈ 2000Kg

6. Over Dimensions:2200*2100*2000mm

NEW DESIGN CNC GLASS NOTCHING MACHINE, For more details or videos

please kindly contact with elaine

+8613622728631(whatsapp) elaine@gtmmachine.com